Vaccum Cleaner

Vacuum Cleaner

Supports Precise and Efficient Control Design

Energy-efficient power management and precision control solutions

enhance cleaning performance and support smart design.

AP SEMI possesses a diverse product lineup for these drive solutions.

01

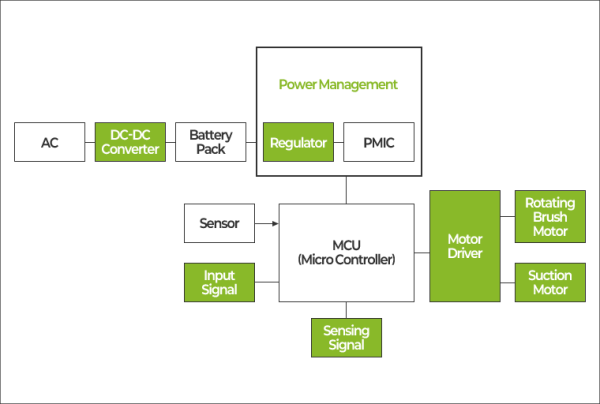

Vacuum Cleaner Block Diagram

02

Product

- Motor Drive

- High Voltage MOSFET

- Bipolar Transistor

- Schottky Barrier Diode

- Switching Diode

- Zener Diode

- Regulator

- OP Amp

03

Solution Configuration

-

01

Motor Drive IC (MDI)

- • Stable drive even at high output → Maintains suction power

- • Precise response to various cleaning modes (Standard/Powerful/Turbo)

-

02

MOSFET

- • Reduced power loss + Extended battery runtime

- • Heat suppression during high-output motor drive, facilitating weight reduction

-

03

Bipolar Transistor (BJT)

- • Provides stable power amplification and switching

- • Efficient auxiliary power control

-

04

Schottky Barrier Diode (SBD)

- • Maximizes efficiency with low forward voltage drop

- • Improved battery charge/discharge efficiency

-

05

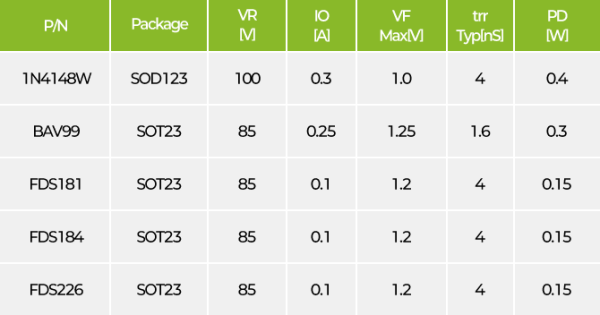

Switching Diode

- • Optimized for PWM inverters and control circuits with fast ON/OFF switching

- • Minimizes power loss and reduces heat generation

-

06

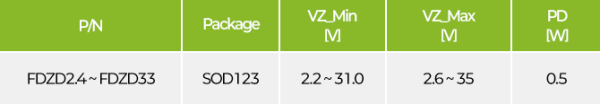

Zener Diode

- • Voltage stabilization and overvoltage protection

- • Stably protects key circuits and ICs from static electricity/surges

-

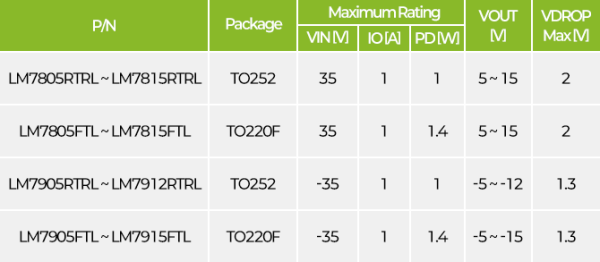

07

Regulator

- • Supplies stable DC voltage for control IC sensors and digital circuits

- • Suppresses voltage fluctuations and stabilizes the system

-

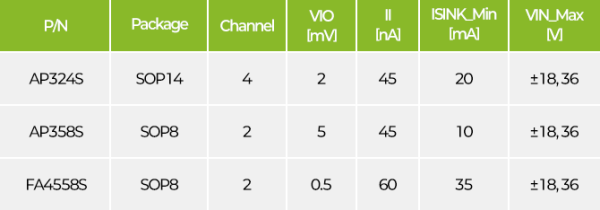

08

OP AMP

- • Battery and motor protection

- • Efficient control through precision measurement

Expected Benefits

-

Enhanced Energy Efficiency

Increased battery runtime with ultra-low Rds(on) MOSFET and high-speed drive

-

Stable High-Output Drive

Heat suppression and suction power maintenance even during high-speed BLDC motor rotation

-

Low-Noise, High-Reliability Operation

Quiet and smooth operation with PWM-based control

-

Enhanced Safety

Extended battery and system lifespan with overcurrent, overvoltage, and temperature protection

04

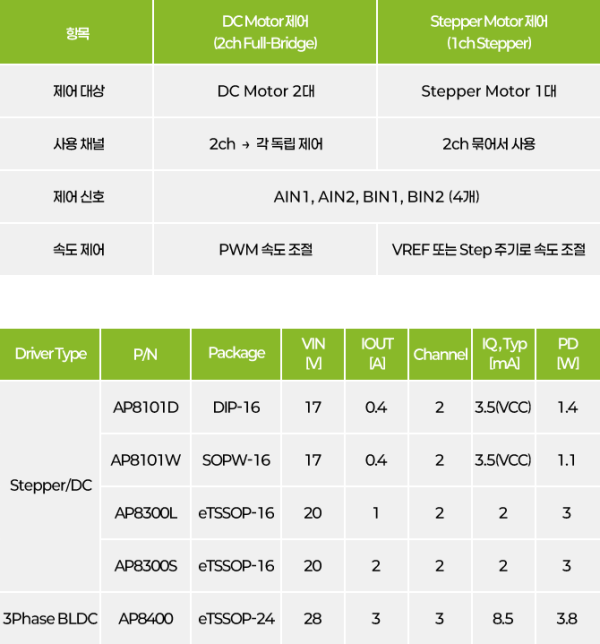

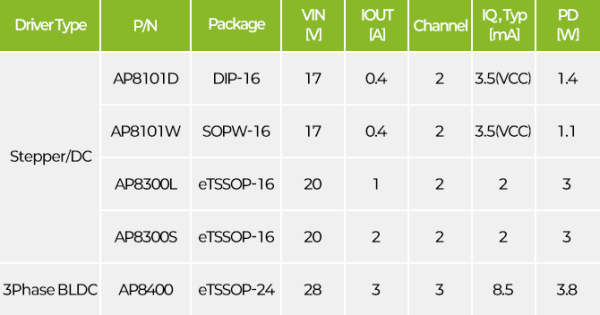

Motor Driver

This IC receives signals from the MCU (Micro Control Unit) and controls the motor.

We supply various package products including Stepper / BDC / BLDC Motors depending on functionality.

Our motor drive ICs minimize power loss through precise speed control and high-efficiency characteristics,

maximizing system reliability.

-

Features

High-Efficiency Power Control: PWM-based BLDC/PMSM motor control

Low Noise, Low Vibration: Responds to various suction modes (Standard/Powerful/Turbo)

Enhanced System Safety: Built-in overcurrent, overvoltage, and overheat protection functions

-

Application Examples

Main Suction Motor (BLDC, tens of thousands RPM high-speed rotation) / Brush Drive Motor, Cyclone Pump

/ Auxiliary Function Stepper Motor (suction nozzle switching, brush height adjustment, etc.)

3Phase BLDC Motor

Main Applications

- Main Suction Motor (BLDC High-Speed Rotation)

- Brush Drive Motor

Features

- High-speed rotation and precise speed control

through inverter control - High energy efficiency and reduced noise/vibration

- Provides powerful suction, responds to various

cleaning modes (Standard/Powerful/Turbo) - No brush wear and noise issues

Stepper Motor

Main Applications

- Brush Height Adjustment

- Suction Nozzle Position Switching and Detailed

Motion Control - Auxiliary Valve and Mechanism Control

(e.g., dust container opening/closing, dust compression device, etc.)

Features

- Rotates at defined step angles

→ Precise position control possible - Optimized for precise dosing drive and

small mechanism control through rotation angle control - Open-loop drive possible

without separate position sensors - Compact and lightweight structure,

applicable to cordless vacuum cleaners

MDI Lineup by

Motor Drive Type

-

2ch Full Bridge Motor

-

1ch Stepper Motor

05

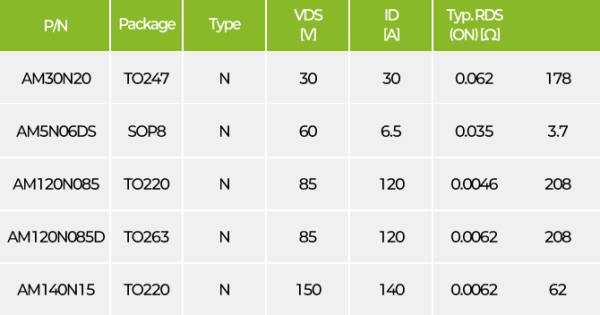

MOSFET for Power Inverter Applications

This is a power switching device that is critical for inverter circuits,

power supply, and motor drives.

We supply various package products including High Voltage MOSFET,

Super Junction MOSFET, and Low Voltage Trench MOSFET.

Through low on-resistance (Rds(on)) and high-speed switching characteristics,

it reduces power loss

and supports high-efficiency operation.

-

Features

High-Speed Switching: Optimized for 30V~150V range

Low Heat, High Efficiency: Minimizes heat generation with ultra-low Rds(on)

Precise Control: High-efficiency power device optimized for inverter drives

System Stability: Overcurrent/overheat protection

-

Application Examples

BLDC Inverter Drive Switch / Battery Protection Circuit (Charge/Discharge Path Switching)

/ Synchronous Rectification Circuit (Charger, DC/DC Converter)

06

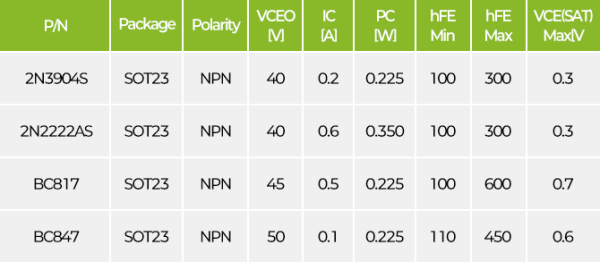

Bipolar Transistor

This is a bipolar transistor that increases efficiency by minimizing low power and loss.

We supply ultra-small package products.

Our bipolar transistors are devices responsible for current amplification and switching,

used in control board relays and low-power switching circuits.

-

Features

Current Amplification: Provides stable drive current

Enhanced Switching Speed: Stable operation in sections requiring signal transition

Circuit Simplification: Enables miniaturization and cost reduction

System Protection: Prevents current overload

-

Application Examples

Control Board Signal Amplification / Auxiliary Drive (Relay, Sub-motor)

07

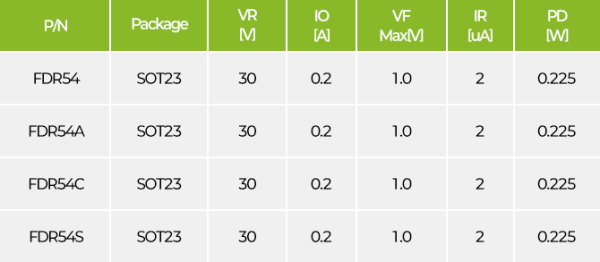

Schottky Barrier Diode

This is a diode using the Schottky barrier generated through metal-semiconductor junction.

We supply ultra-small package products.

Our Schottky barrier diodes minimize power loss with low forward voltage

and fast switching characteristics, applied to power rectification,

reverse current blocking, and SMPS circuits.

-

Features

Low Power Loss: Low forward voltage drop reduces energy loss

and provides electricity cost savingsHigh-Speed Switching: Stable operation in sections requiring fast signal transition

such as PWM control and inverter circuitsEnhanced System Stability: Protects electronic components by minimizing

overvoltage during reverse current and switchingMiniaturization

and Weight Reduction: Low heat simplifies thermal design, enabling overall circuit miniaturization -

Application Examples

Battery Reverse Current Blocking / Power Section Rectification Circuit

/ Freewheeling Diode Replacement in Inverter and DC/DC Converter Section (Low Voltage)

08

Switching Diode

This is a switching diode for rectification and switching.

We supply various package products with short reverse recovery time (trr).

Our switching diodes are used in circuits requiring fast ON/OFF switching,

applied to control signals and small switching circuits.

-

Features

High-Speed Switching Stability: Accurate signal transmission in PWM inverter and motor control

circuits with fast reverse recovery in nS unitsSystem Efficiency Improvement: Reduces heat generation by minimizing power loss, improving overall system efficiency

Miniaturization

and Weight Reduction: Low heat simplifies thermal design, enabling overall circuit miniaturization -

Application Examples

Control Board Signal Circuits / Motor Drive Auxiliary Circuits

09

Zener Diode

This is a Zener diode used in constant voltage circuits.

We supply ultra-small package products for protecting

ICs from surges or static electricity.

Our Zener diodes safely conduct current above a specific voltage,

maintaining constant voltage and protecting circuits from overvoltage.

-

Features

Voltage Stabilization: Supplies constant voltage to key circuits despite input voltage fluctuations

Circuit Protection: Protects major components such as motors and inverters by distributing current during overvoltage

Enhanced System Reliability: Ensures stable operation despite power fluctuations or external abnormal voltages

Versatile Design Application: Customizable application to various circuit conditions according to Zener voltage selection

-

Application Examples

MCU and Drive IC Protection Circuit / Voltage Stabilization of Sensor and Communication Circuits

10

Regulator

This is a regulator used to regulate and maintain input voltage or pressure at a stable level.

We supply various package products to ensure stable operation of connected devices.

Our regulators are used to provide stable power supply

to control boards, sensors, and microcontrollers.

-

Features

Voltage Stabilization: Improves circuit operation reliability

Noise Suppression: Minimizes sensor signal errors

System Protection: Includes overvoltage/overheat protection functions

PCB Design Simplification: Small package application possible

-

Application Examples

Main Control Board / Sensor and MCU Power Supply

11

OP Amp

This is an OP AMP that amplifies and outputs the voltage difference between two input terminals.

We supply various package products for amplification, operation, and filtering.

Our OP AMP is used to ensure stability in sensor interfaces and control.

It enables accurate measurement, protection, and control,

used in solutions that simultaneously improve energy efficiency and product reliability.

-

Features

High Input Impedance / Low Output Impedance: Can amplify sensor signals without distortion

Low Offset Voltage & Drift: Stable operation during long-term use

Low Noise Characteristics: Improves sensor measurement reliability

Rail-to-Rail Input

/Output Support: Advantageous even in low voltage drive circuits -

Application Examples

Battery Voltage/Current Monitoring / Motor Current Sensing and Protection Circuit

/ Dust Sensor Signal Amplification, Environmental Sensor Calibration

-

이전글

-

다음글