OBC

EV On-Board Charger

Device that Supplies Power to OBC Lighting Equipment

An EV (Electric Vehicle) charger is a device that supplies power to electric vehicle batteries,

converting alternating current (AC) power from the power grid

to direct current (DC) power for battery charging.

Charging methods are broadly divided into slow charging through the vehicle's internal on-board charger,

and fast charging where the charging station's rectifier supplies power directly,

and can be utilized in various forms such as portable chargers or wireless charging

depending on convenience and needs.

Particularly recently, with India discontinuing internal combustion engine rickshaw sales and

converting entirely to electric rickshaws, sales volumes are rapidly increasing, and as the market

expands to Southeast Asia, demand for 3-wheels (auto rickshaw) chargers is also rapidly increasing.

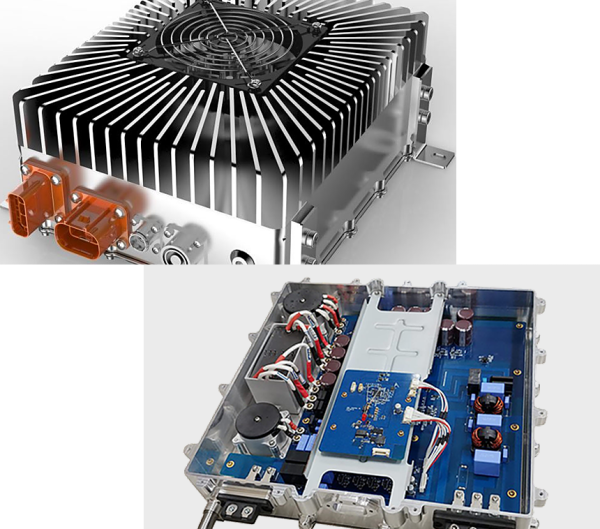

On-Board Charger

On-Board Charger

An On-Board Charger (OBC) is a device built into electric vehicles (EV)

that converts alternating current (AC) power supplied from external sources

to direct current (DC) power for storage in the vehicle battery.

Used during slow charging, it converts AC power introduced through household plugs or

charging connectors to DC power suitable for EV batteries to enable charging.

AP SEMI has launched Super Junction MOSFETs with significantly improved TRR speed

through electron irradiation, offering a diverse lineup of high-power MOSFET and

RECTIFIER products suitable for fast switching speed drives.

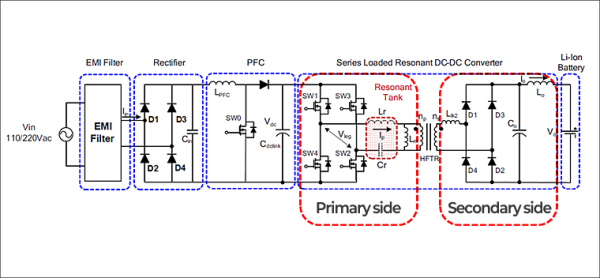

01

Power Stage Topology

of OBC for EV

02

High Power Transistor

High Power TR

In LED converters (SMPS), power MOSFETs are used as power TRs

that convert input voltage to desired DC voltage and play a switching role

in supplying stable current and voltage to LEDs.

Since MOSFET characteristics significantly affect converter efficiency

and noise reduction performance, MOSFET characteristics must be

fully considered when designing LED lighting.

MOSFET Application 01

High-Efficiency Power Control

Since converter efficiency varies depending on MOSFET characteristics (e.g., on-resistance, switching speed),

select MOSFETs with high efficiency.

MOSFET Application 02

Heat Generation

OBC converters with high current generate heat, so consider appropriate heat dissipation measures

and select MOSFETs with low heat generation and good durability. Since heat dissipation capability

varies greatly depending on package type, check PD (Power Dissipation) before selection.

MOSFET Application 03

Voltage and Current

Select MOSFETs with sufficient specifications to handle

the input voltage and output current required for LED converters.

03

MOSFET Types and Characteristics

-

01

Planar MOSFET

• Advantages

Simple structure, easy to manufacture with low cost, and has low noise characteristics

for good EMI performance.• Disadvantages

Large device ON resistance (RDS(on)), slow switching speed, increased device size

at the same voltage rating, and lower efficiency. -

02

Super Junction MOSFET

• Advantages

ON resistance (RDS(on)) and gate charge (Qg) are significantly lower than Planar MOSFETs,

improving efficiency with high-speed switching performance.• Disadvantages

Larger PN Junction area than Planar type results in higher reverse recovery current (irr)

during ON-OFF transitions, tends to have higher noise during high-speed switching, and is

more expensive due to highly integrated structure implementation. -

03

SiC MOSFET (Silicon Carbide)

• Advantages

Has wider bandgap than Si, delivering excellent performance even at high temperatures and voltages,

providing high efficiency with low conduction loss and high switching speed. Particularly suitable

for power conversion devices such as electric vehicle inverters and OBC (onboard chargers).• Disadvantages

Requires high-temperature processes above 2000℃, which is time-consuming and significantly

increases costs. High price and reliability issues (SiO2-SiC interface problems) result in low yields,

which can be a supply issue during commercialization. -

04

GaN MOSFET (Gallium Nitride)

• Advantages

Higher electron mobility than SiC enables very fast switching speeds, low conduction resistance

minimizes power loss and increases power density, reducing size and weight of compact power

supply devices while improving efficiency.• Disadvantages

Higher conductivity than SiC can limit possible power density, and yield and reliability

issues still exist.

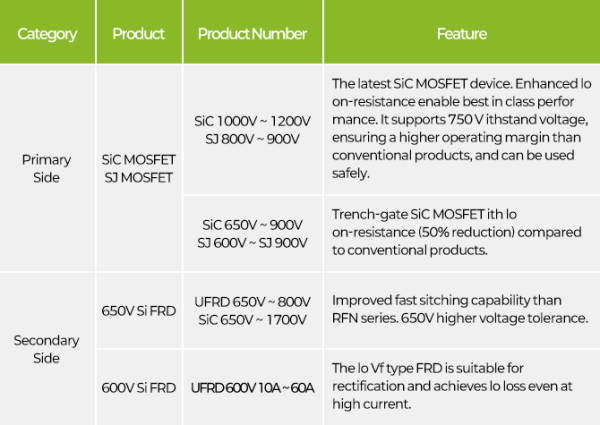

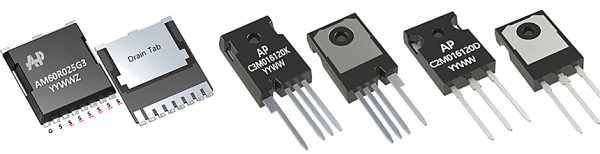

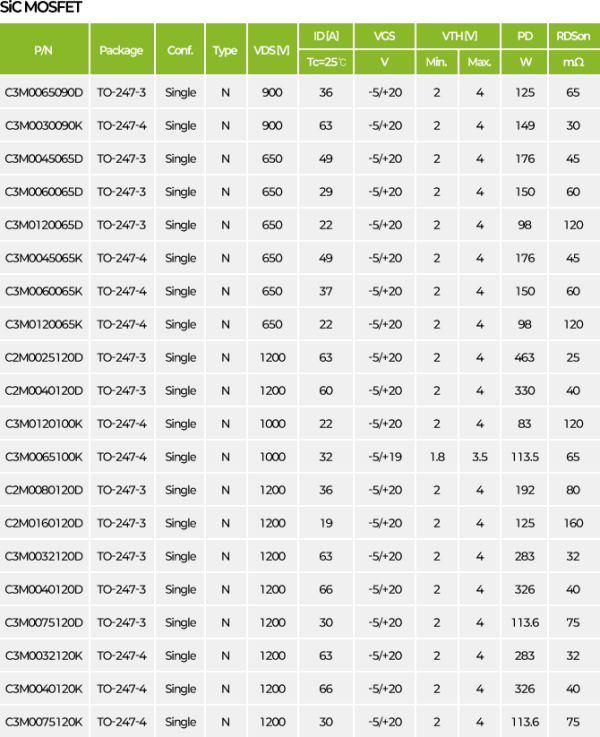

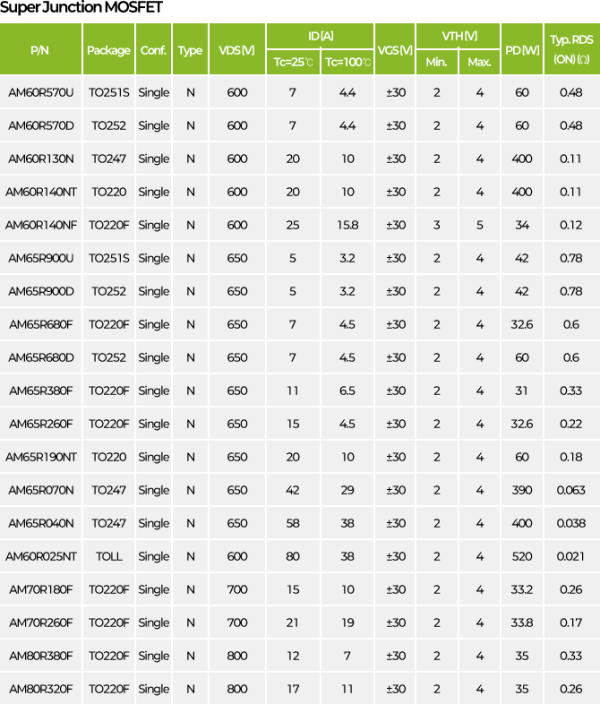

MOSFET Lineup

04

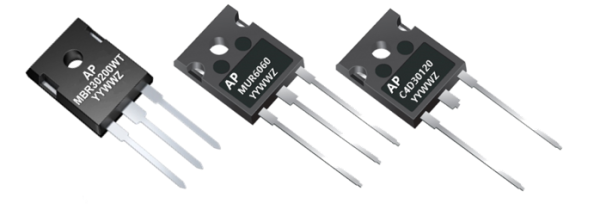

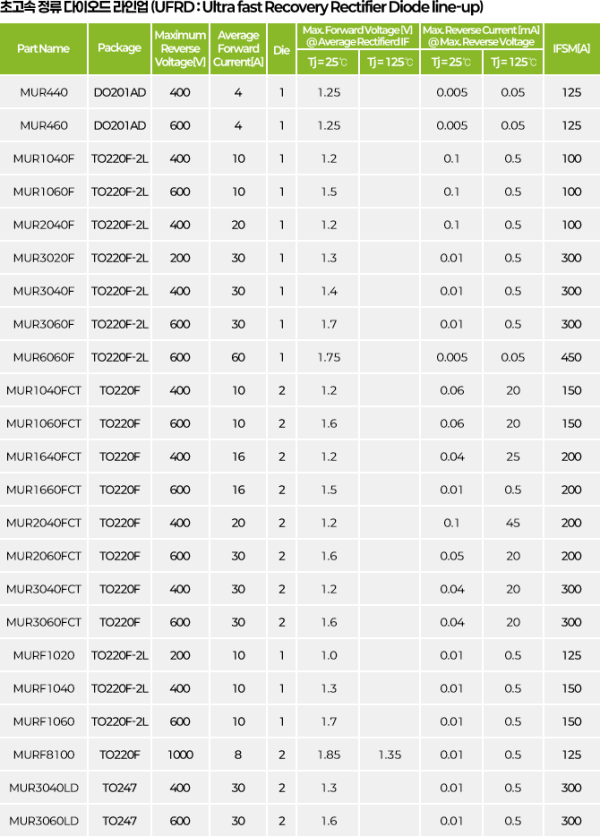

Rectifier Diode

Rectifier Diode

Since the forward voltage of rectifier diodes in power converters is directly related to power loss,

high-efficiency power diodes must be used to increase efficiency.

By using diodes with short reverse recovery time

(TRR: Reverse Recovery Time)

to reduce switching losses, efficiency is increased and losses are minimized.

Standard Rectifier

Rectifier Diode with slow reverse recovery characteristics with TRR of 2-20 micro Sec.,

mainly used in primary rectification of adapters or power supplies or low-frequency circuits such as toys

Fast Recovery Rectifier

Rectifier Diode with TRR of 100~750 nano Sec., used in high-frequency (20~50Khz) circuits

Ultra Fast Recovery Rectifier

Rectifier Diode with TRR of 35~75 nano Sec., generates less heat than Fast Recovery Rectifier,

mainly used in high-voltage (400V~1000V), high-frequency (50Khz or higher) circuits

Ultra High Efficient Rectifier

High-speed rectifier Diode with TRR of 10~35 nano Sec., low resistance ($V_F$) reduces heat generation.

Used in low-voltage (up to 200~600V), high-frequency (50~200Khz) circuits

Schottky Barrier Rectifier

Very low internal resistance and fast operation speed, but low operating voltage and high leakage current.

Mainly used in high-frequency, high-current, low-voltage rectification

Ultra Low $V_F$ Schottky Rectifier

Schottky rectifier that uses trench process compared to general Schottky to significantly reduce forward voltage

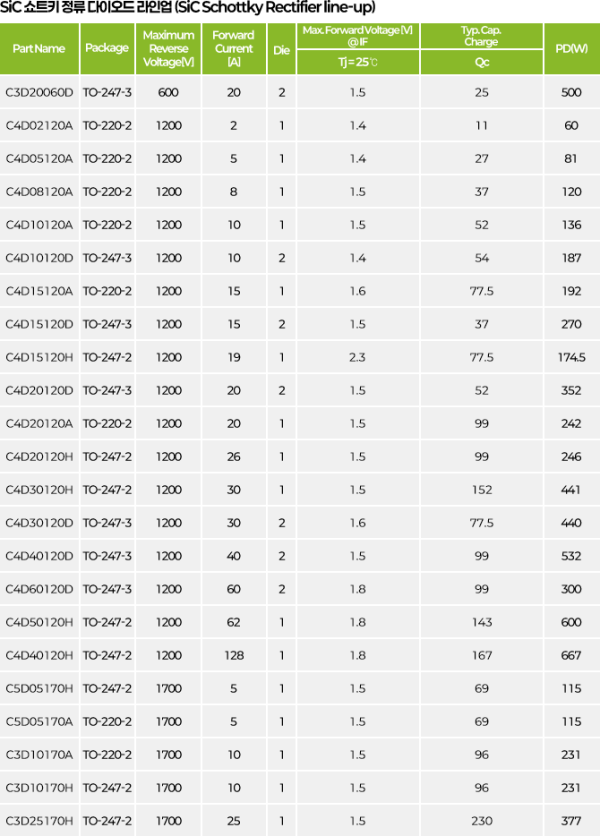

SiC Schottky Diode

SiC Schottky diodes are Schottky diodes made using silicon carbide (SiC) semiconductors,

featuring low forward voltage drop, high-speed switching characteristics, excellent stability at high temperatures,

and virtually no reverse recovery current, enabling increased power efficiency and system simplification.

Particularly preferred products for high-power OBC and EV Chargers. However, the manufacturing process is

difficult and requires high-temperature operations, resulting in high costs, with prices about 10 times higher

than silicon Schottky diodes.

05

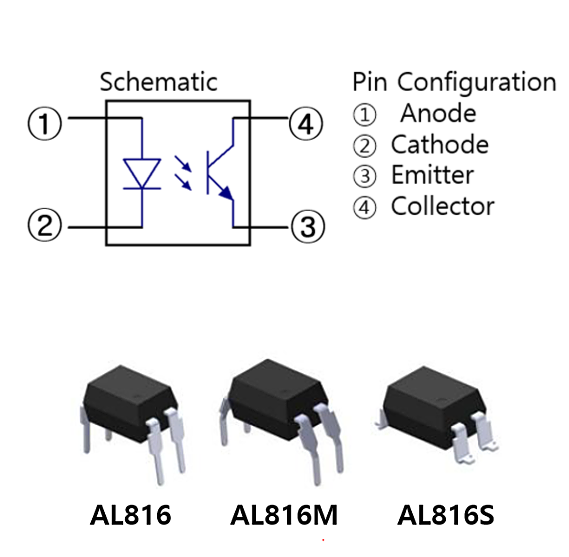

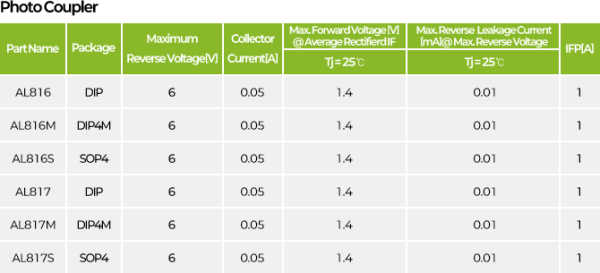

Photocoupler

Photo Coupler, Optocoupler, Isolator

A photocoupler is a device that transmits signals between the input and output circuits

in an electrically isolated state by activating the phototransistor (light-receiving section)

with light emitted when the internal LED turns on. When the electrical signal of the input circuit

flows current to the LED to generate light, this light passes through the phototransistor

to flow current to the output circuit, and through this,

signal transmission between the two circuits is achieved.

06

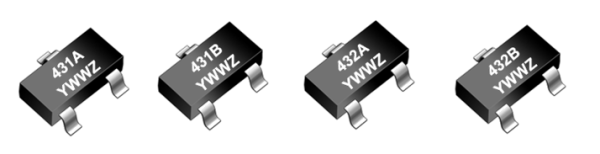

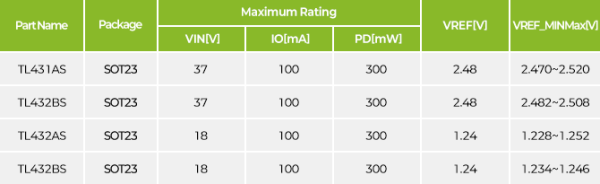

Shunt Regulator

Shunt Regulator

A shunt regulator is a device that regulates voltage to maintain stable output

despite input voltage fluctuations or load changes.

'Shunt' refers to a method of regulating voltage by connecting in parallel

to the load that conducts current, operating on the same principle as a shunt

to supply stabilized power at a specific voltage level.

-

이전글이전글이 없습니다.

-

다음글